We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

On-Site Load Testing

DON'T GUESS. TEST. BUT INTERPRET IT CORRECTLY.

Did you know anchors/fixings used in construction equate to less than 0.5% of the overall project value? In percentage terms, I think we can all agree that is quite small. This often leads me to wonder, why are anchors/fixings not given the respect they deserve?

Quite often, it seems that certain anchor tests are seen as a 'box ticking' exercise, but they shouldn't be seen in that light. After all, carrying out compliant anchor tests can provide peace of mind in two areas. Firstly, it helps the specifier to identify a suitable anchor for a given substrate and secondly it can provide proof of a compliant installation.

What is on-site load testing?

- A tensile test is conducted either to determine the capacity of the anchor or to prove installation safety.

- Anchor testing is the process whereby an anchor/fixing is pulled to a designated test load. From this, the performance of the anchor./fixing can be quantified.

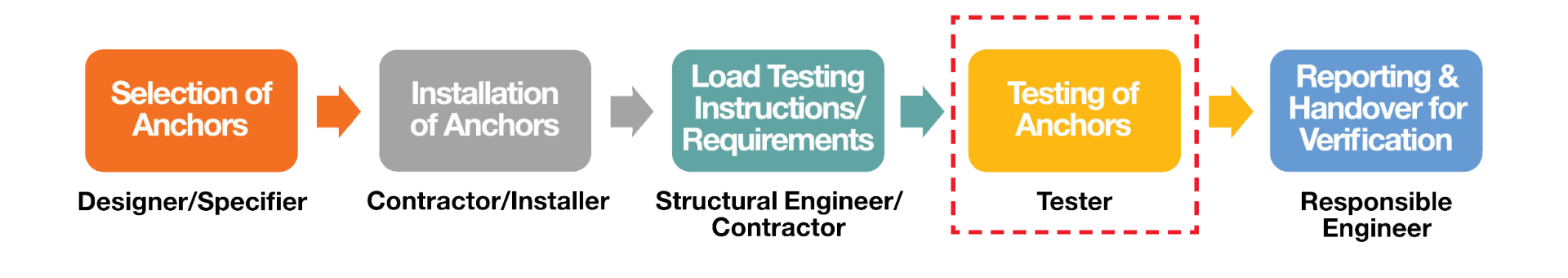

Flowchart for overall process of selection, installation, and testing of anchors/fixings

ADVANTAGES OF ANCHOR TESTING?

- Anchor testing generically referred to as 'pull testing' plays an important role in the selection and post verification of an installation.

- In many refurbished buildings the design strength of the substrate is not known. In cases like these, an allowable load test (proof load test) must be carried out on-site to ensure that the appropriate design load can be verified and the correct anchor/fixing can be selected.

- To verify a post-installed anchor, a 'pull out test' or 'proof test' is highly recommended.

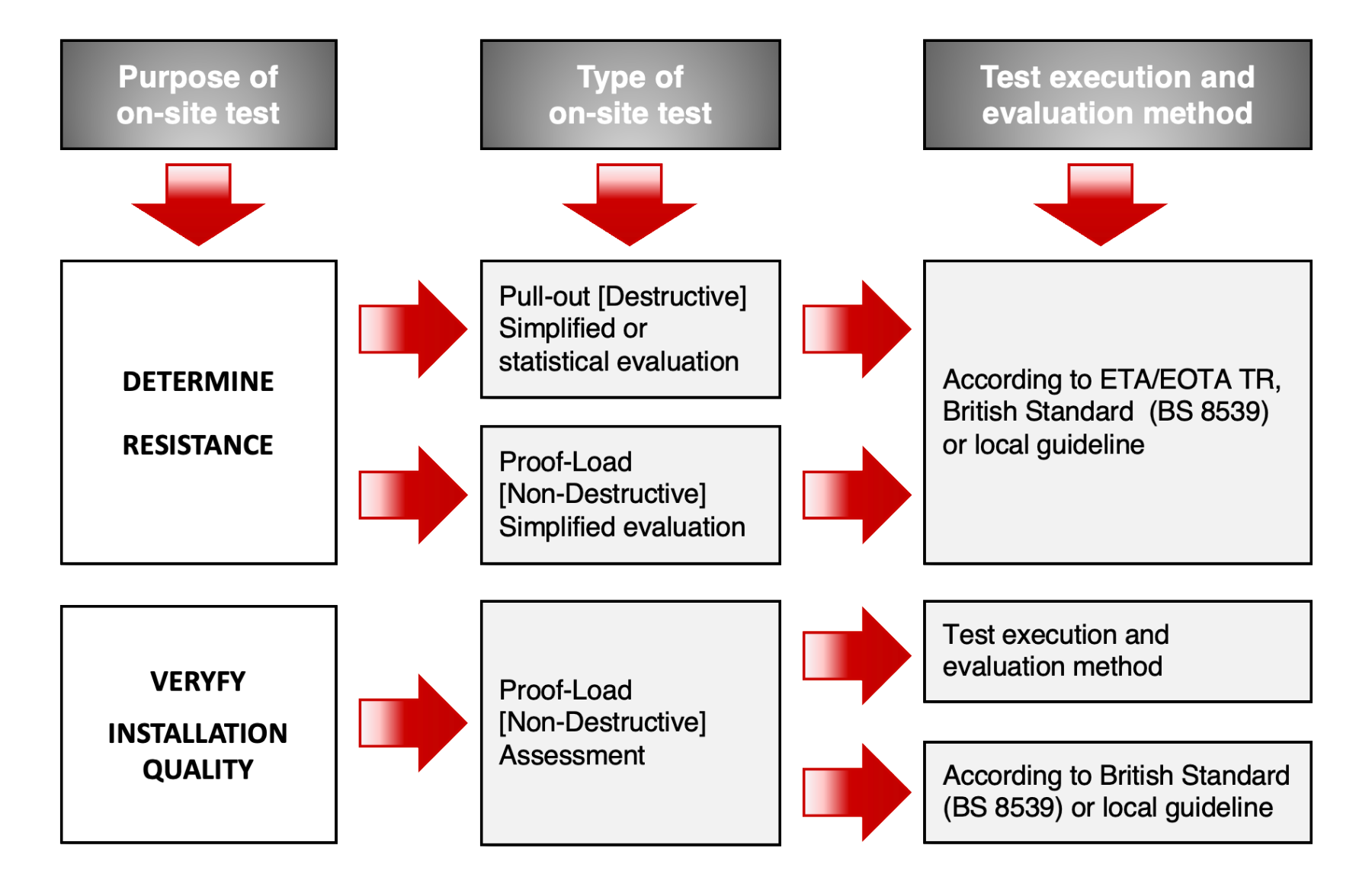

PURPOSE & TYPES OF ON-SITE TEST

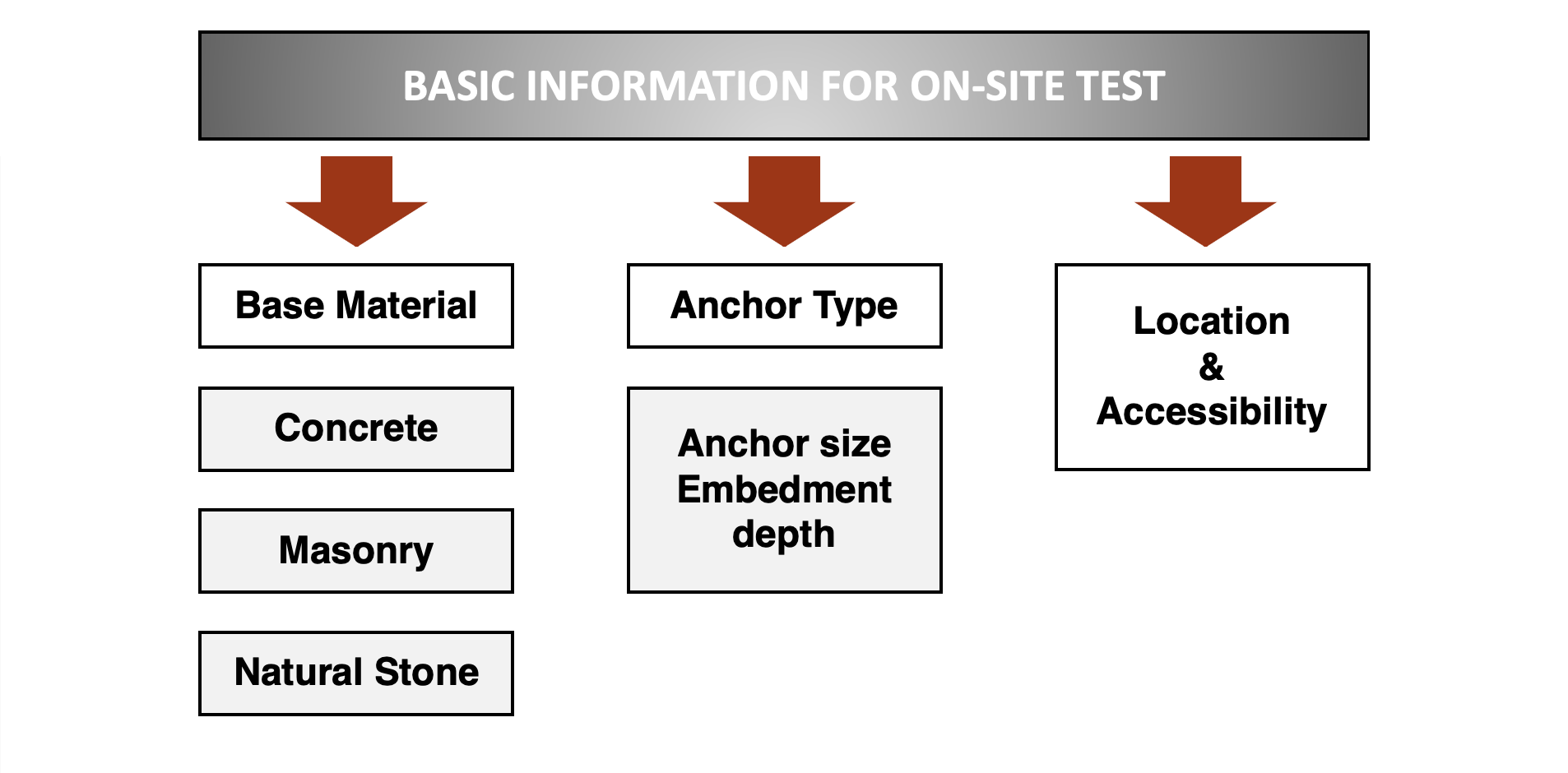

THINGS WE NEED TO KNOW

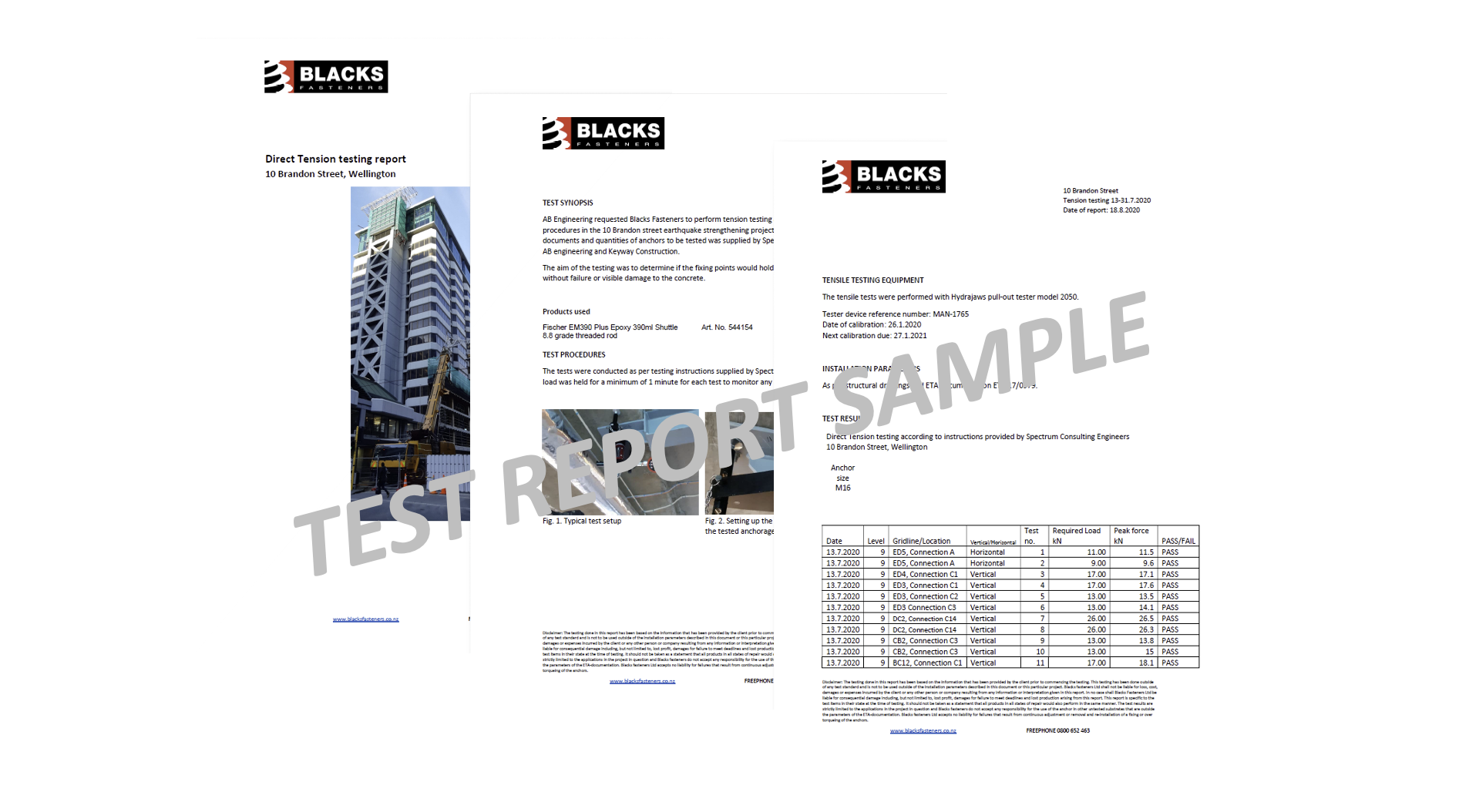

WHAT DO WE RECORD IN OUR REPORTS?

Information such as:

- Administration details *date of test, reason for test, name of person requesting test, unique reference test, client's company name, site location, contact name, and position).

- Anchor/application details: name of the manufacturer, anchor type, size, and finish, proposed application of anchor, design resistance and manufacturer's recommended resistance in the base material concerned (for proof tests).

- Test objectives, test location, base material, installation details, test equipment details, test results, method statement, gauge calibration certificate.

- Additional information might be required depending on the specific circumstances of the test.

APPLICATIONS

For more information, please contact our Technical Field Engineer – Emmanuel Mururi [email protected] or 0276634525 |

|